This manual provides essential guidelines for the operation, maintenance, and safety of equipment covered under model number 6666-36, ensuring optimal performance and compliance with safety standards.

Overview of the Manual

Manual 6666-36 serves as a comprehensive guide for the operation, maintenance, and troubleshooting of associated equipment. It outlines technical specifications, safety protocols, and installation procedures, ensuring users can utilize the equipment efficiently. The manual includes detailed electrical schematics, step-by-step installation instructions, and a maintenance schedule to prolong equipment lifespan. Additionally, it provides appendices with a glossary of terms and contact information for support. Designed for both professionals and general users, this manual emphasizes safety and optimal performance, making it an indispensable resource for anyone working with the equipment covered under model number 6666-36.

Importance of the Manual for Equipment Operation

Importance of the Manual for Equipment Operation

Manual 6666-36 is crucial for safe and effective equipment operation. It provides detailed instructions, warnings, and guidelines to prevent accidents and ensure optimal performance. By following the manual, users can avoid costly repairs and downtime. Adherence to the outlined procedures minimizes risks and extends equipment lifespan. The manual is essential for troubleshooting common issues and understanding critical safety measures. It serves as a primary reference for operators, technicians, and maintenance personnel, ensuring compliance with industry standards and manufacturer recommendations. Proper use of the manual guarantees efficient and reliable operation of the equipment covered under model number 6666-36.

Technical Specifications of Equipment Covered in Manual 6666-36

Model 6666-36 features 36 disks, a width of 4.7 meters, and is in excellent condition, ready for immediate operation with specifications detailed for optimal performance and reliability.

Key Features and Components

Model 6666-36 is equipped with 36 high-efficiency disks, designed for optimal performance, and features a robust width of 4.7 meters. The equipment is in excellent condition, ready for immediate operation. Key components include advanced operational systems, durable construction, and user-friendly controls. The manual highlights factory-produced specifications, ensuring reliability and longevity. Electrical schematics are provided for seamless integration and troubleshooting. This model is designed for heavy-duty applications, with a focus on precision and safety, making it a versatile solution for various industrial needs. Its compatibility with standard operational parameters ensures efficient workflow and minimal downtime.

Compatibility and Operational Parameters

Manual 6666-36 outlines the equipment’s compatibility with various systems and operational parameters for seamless integration. The model is designed to work efficiently within specified ranges, ensuring optimal performance across diverse environments. Its operational parameters include precise temperature and pressure settings, while compatibility extends to multiple industrial applications. The equipment is engineered to meet rigorous standards, ensuring smooth operation with existing infrastructure. By adhering to these guidelines, users can maximize efficiency and minimize downtime, leveraging the equipment’s full potential. Proper alignment with operational parameters is crucial for maintaining safety and productivity. Regular checks ensure compliance with recommended specifications.

Safety Guidelines and Precautions

Adhere to all safety guidelines in Manual 6666-36, including proper attire and equipment handling. Follow warning labels to avoid hazards. Failure to comply may result in injury or damage.

Warning Labels and Critical Safety Instructions

Manual 6666-36 emphasizes the importance of adhering to warning labels and critical safety instructions to prevent accidents. Always read and comply with safety precautions before performing any operation or maintenance. Avoid unauthorized repairs or adjustments, as specified in the manual, to ensure equipment integrity. Failure to follow guidelines may result in serious injury, equipment damage, or operational failure. Proper attire, including safety gear, must be worn when interacting with the equipment. Refer to the manual for detailed instructions on handling critical components and emergency procedures to maintain a safe working environment.

Emergency Procedures and Risk Assessment

Manual 6666-36 outlines critical emergency procedures to ensure operator safety and equipment protection. In case of malfunctions or hazards, immediately disconnect power and follow evacuation protocols. Identify emergency exits and ensure accessibility. Regular risk assessments are essential to identify potential hazards, such as electrical failures or mechanical breakdowns. Evaluate the severity of risks and implement mitigation strategies. Always refer to the manual for detailed emergency response plans and guidelines. Proper training and preparedness are vital to minimize risks and ensure effective handling of critical situations, safeguarding both personnel and equipment.

Installation and Maintenance Procedures

This section provides detailed installation steps and maintenance schedules for optimal performance. Follow guidelines to ensure safety and efficiency, adhering to manual instructions.

Step-by-Step Installation Guide

The manual outlines a comprehensive installation process for equipment model 6666-36. Begin by preparing the site, ensuring all components are unpacked and inspected for damage. Follow the sequence: mount the base, assemble major components, and connect electrical systems. Refer to the provided diagrams for accurate connections. Tighten all bolts securely and test functionality before full operation. Always use tools specified in the manual to avoid damage. Ensure compliance with safety guidelines to prevent accidents during installation. Proper alignment and leveling are crucial for optimal performance. Complete the process with a final inspection and system test.

Recommended Maintenance Schedule

Regular maintenance is crucial for ensuring the longevity and efficiency of equipment model 6666-36. The manual advises performing routine inspections every 500 operational hours, including lubrication of moving parts and checking electrical connections. Replace wear-and-tear components annually or as specified. Clean filters monthly to maintain airflow and prevent overheating. Schedule a professional service every 2,000 hours for comprehensive checks. Adhere to the maintenance schedule to avoid unexpected downtime and ensure compliance with safety standards. Proper record-keeping of maintenance activities is recommended for tracking and future reference.

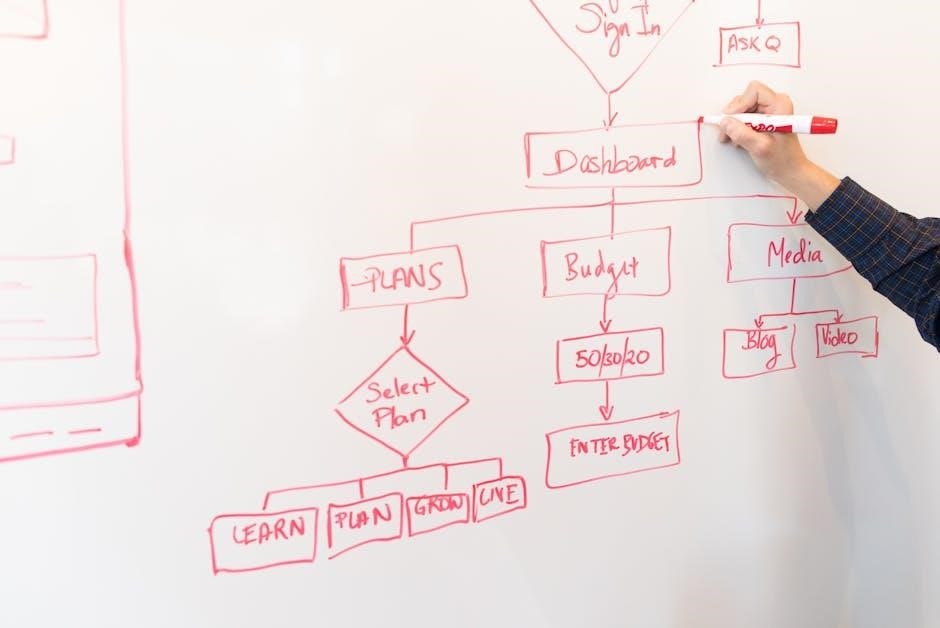

Electrical Schematics and Diagrams

The manual provides clear electrical schematics and diagrams for model 6666-36, aiding in troubleshooting and understanding circuit connections. Refer to the wiring diagrams for optimal setup.

Understanding the Circuit Diagrams

The circuit diagrams in Manual 6666-36 provide a detailed visual representation of the electrical system, including components, connections, and power flow. These diagrams are essential for troubleshooting and maintenance, offering a clear understanding of how the equipment operates. By analyzing the symbols, labels, and pathways, users can identify potential issues and ensure proper repairs. The diagrams also highlight critical safety points, such as voltage levels and grounding requirements, to prevent accidents. Familiarizing yourself with these schematics is crucial for safe and effective equipment management.

Refer to the diagrams for component locations, wiring configurations, and operational sequences. This ensures accurate diagnostics and efficient problem-solving.

Troubleshooting Common Electrical Issues

Troubleshooting Common Electrical Issues

Manual 6666-36 provides detailed guidance for identifying and resolving common electrical issues. Start by consulting the circuit diagrams to locate faulty components or connections. Check for power supply disruptions, loose wiring, or damaged fuses. Verify grounding systems to ensure proper electrical safety. Refer to the troubleshooting section for step-by-step solutions to issues like short circuits or malfunctioning switches. Always follow safety protocols, such as disconnecting power before repairs. If problems persist, contact certified professionals for assistance.

Regular maintenance and adherence to the manual’s instructions can prevent many electrical issues, ensuring reliable equipment performance and longevity.

Appendices and Additional Resources

The appendices include a glossary of terms, contact information for support, and references for further reading, ensuring comprehensive understanding and accessibility of additional resources for optimal performance.

Glossary of Terms and Abbreviations

Glossary of Terms and Abbreviations

The glossary provides clear definitions for technical terms and abbreviations used throughout Manual 6666-36, ensuring users understand key concepts and terminology essential for equipment operation and maintenance. This section covers abbreviations like “HDKAG” and terms related to electrical components, such as “circuit diagrams” and “OptiSwitch,” aiding in troubleshooting and setup. It serves as a quick reference, enhancing comprehension and practical application of the manual’s instructions, ensuring safe and effective use of the equipment. Proper understanding of these terms is crucial for adhering to safety guidelines and operational protocols outlined in the manual.

Contact Information for Support and Spare Parts

Contact Information for Support and Spare Parts

For inquiries or assistance, contact the manufacturer’s support team at support@manufacturer.com or call +1-800-6666-36. Office hours are Monday to Friday, 8 AM to 5 PM EST. Visit the official website at www.manufacturer.com for online support resources. Spare parts can be ordered directly through authorized distributors listed in the manual. Ensure to provide the model number (6666-36) for accurate assistance. Emergency support is available 24/7 at +1-888-6666-36. Refer to the manual’s appendix for detailed contact information and regional support centers.

Adhering to this manual ensures optimal equipment performance, safety, and longevity. Always follow guidelines for efficient operation and maintenance.

Final Tips for Optimal Equipment Performance

Regularly inspect and maintain equipment as per the manual to ensure peak performance. Follow all safety guidelines and update software if applicable. Schedule routine checks and adhere to maintenance schedules to prevent unexpected downtime. Keep the operating environment clean and free from debris. Refer to the troubleshooting section for common issues and resolve them promptly. Always use genuine spare parts for repairs to maintain reliability. Proper storage and handling of equipment components are crucial for longevity. By following these tips, you can maximize efficiency and extend the lifespan of your equipment.

Importance of Adhering to Manual Instructions

Importance of Adhering to Manual Instructions

Adhering to the instructions in Manual 6666-36 is crucial for ensuring safe and efficient operation of the equipment. Failure to follow guidelines can lead to malfunctions, safety hazards, and voiding of warranties. The manual provides detailed procedures for installation, maintenance, and troubleshooting, which are essential for optimal performance. Ignoring these instructions may result in equipment damage or personal injury. Always refer to the manual before performing any repairs or adjustments, as specified in the safety guidelines. Compliance ensures reliability, longevity, and adherence to industry standards, making it indispensable for operators and technicians. Proper adherence is key to minimizing risks and maximizing productivity.