Welcome to the Bissell ProHeat 2X repair manual, your comprehensive guide to understanding and maintaining your carpet cleaner. This manual provides detailed parts diagrams, troubleshooting tips, and step-by-step repair instructions to help you keep your machine running efficiently. Whether you’re replacing the front nozzle assembly or addressing wiring issues, this resource ensures you have the knowledge and tools needed for successful repairs and maintenance.

Overview of the Importance of Parts Diagrams

Parts diagrams are essential for effectively repairing and maintaining the Bissell ProHeat 2X. They provide a visual representation of the machine’s components, making it easier to identify and locate specific parts. By referring to these diagrams, users can understand how different elements connect and function together. This clarity helps prevent mistakes during repairs and ensures that the correct parts are ordered and installed. Additionally, parts diagrams aid in troubleshooting by highlighting relationships between components, which can be critical for diagnosing malfunctions. Whether replacing the front nozzle assembly or addressing wiring issues, these diagrams serve as a cornerstone for successful maintenance and repair efforts.

Understanding the Wiring Diagram

The wiring diagram provides a detailed visual map of the Bissell ProHeat 2X’s electrical system, helping users identify components and their connections for effective troubleshooting and safe repairs.

How to Read the Wiring Diagram for Effective Repairs

Start by locating the wiring diagram on page 20 of the Bissell ProHeat 2X manual. Identify each component, such as the motor and heater, and trace their connections. Use the diagram’s legend to understand symbols and wire colors, which often indicate live, ground, and neutral wires. To repair, disconnect power, then follow the diagram to isolate and test faulty wires or components. Refer to online guides or videos for additional clarification if needed, and always prioritize safety by unplugging the machine before starting work.

Plumbing Schematics Explained

Plumbing schematics illustrate the Bissell ProHeat 2X’s water and solution flow systems, showing connections between components like pumps and tanks. They aid in identifying blockages and guiding repairs effectively.

Comprehensive Guide to the Plumbing System

The Bissell ProHeat 2X plumbing system is designed to efficiently distribute water and cleaning solution. Key components include the water pump, solution tank, and spray nozzles. Understanding the flow diagram helps identify blockages or leaks. Regular maintenance, such as checking for kinks in hoses and cleaning spray tips, ensures optimal performance. Refer to the exploded parts diagram for locating specific plumbing parts. Always use genuine Bissell replacement components to maintain system integrity. Following the manual’s guidelines for disassembly and reassembly ensures proper plumbing system repair. This guide provides step-by-step instructions to troubleshoot and fix common plumbing issues, keeping your cleaner operational.

Key Components of the Bissell ProHeat 2X

The Bissell ProHeat 2X features essential components like the front nozzle assembly, lower brush housing, and upper housing assembly. These parts work together to ensure effective cleaning and machine longevity.

Front Nozzle Assembly: Function and Replacement

The front nozzle assembly on the Bissell ProHeat 2X is a critical component that directs cleaning solutions and water onto surfaces. It ensures even distribution for effective cleaning. Over time, it may clog or wear out, requiring replacement. To replace it, first empty the tank and remove any debris. Use a screwdriver to detach the assembly from the machine. Install the new part securely, ensuring proper alignment. Refer to the exploded diagrams in the manual for precise guidance. Regular maintenance of this part prevents issues like uneven cleaning or reduced performance, keeping your ProHeat 2X functioning optimally.

Lower Brush Housing: Maintenance and Repair

The lower brush housing on the Bissell ProHeat 2X plays a vital role in maintaining the machine’s cleaning efficiency. Regular maintenance is essential to prevent clogs and wear. Inspect the housing for debris buildup and clean it thoroughly after each use. If brushes are worn or damaged, replace them promptly to avoid reduced cleaning performance. For repairs, refer to the exploded diagrams in the manual to locate and remove the housing. Replace any faulty components, such as bearings or seals, to ensure proper function. Proper care extends the lifespan of the lower brush housing and keeps your ProHeat 2X operating at peak performance.

Upper Housing Assembly: Troubleshooting Common Issues

Troubleshooting the upper housing assembly of your Bissell ProHeat 2X involves identifying common issues like clogged water tanks or faulty sensors. Start by inspecting the assembly for blockages, especially around the water flow channels. If the machine isn’t dispensing water, check the tubes and connections for kinks or damage. Refer to the parts diagram to locate and remove the upper housing for closer examination. Clean or replace any obstructed parts, and ensure all connections are secure. Addressing these issues promptly prevents further damage and ensures optimal performance of your cleaner. Always use genuine Bissell parts for replacements to maintain reliability and functionality. Regular maintenance can help avoid these problems altogether.

Troubleshooting Common Issues

Identify and resolve malfunctions in your Bissell ProHeat 2X by referencing the repair manual and parts diagram. Address common issues like clogged nozzles or faulty wiring promptly for optimal performance.

Identifying and Resolving Machine Malfunctions

Use the Bissell ProHeat 2X repair manual to diagnose and fix common issues. Start by consulting the parts diagram to locate components like the front nozzle or brush housing. Check for clogs in the nozzle or dirty filters, which can reduce suction power. If the machine isn’t heating, inspect the wiring diagram for loose connections or faulty thermal cutoffs. For brush malfunctions, ensure the belt is intact and properly aligned. Refer to the troubleshooting guide for step-by-step solutions. Clean or replace damaged parts as needed, using genuine Bissell components for optimal performance. Regular maintenance can prevent many of these issues, ensuring your cleaner operates efficiently.

Step-by-Step Repair Process

Use the Bissell ProHeat 2X user manual and exploded diagrams to accurately identify and locate parts, ensuring correct repairs and maintenance with precise part numbers and clear visuals.

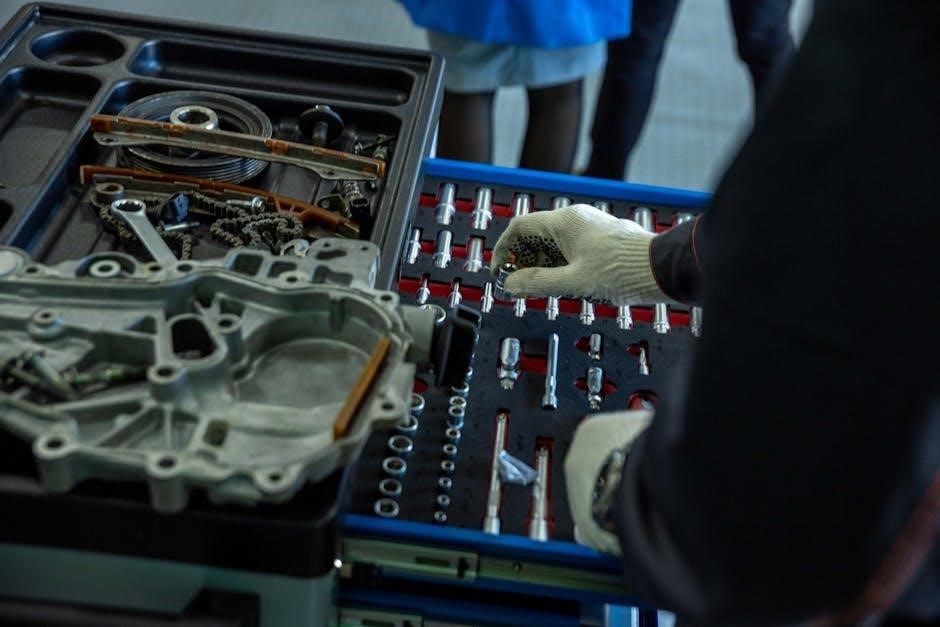

Preparing Tools and Safety Precautions

Before starting any repair, gather essential tools like screwdrivers, pliers, and wrenches. Ensure the machine is unplugged to avoid electrical hazards. Wear protective gloves and eyewear. Consult the manual for specific part locations. Clear your workspace for better accessibility. Refer to exploded diagrams for visual guidance. Always disconnect power before disassembling components. Keep replacement parts organized to avoid misplacement. Follow safety guidelines to prevent injuries and ensure proper repairs. Familiarize yourself with the wiring diagram to avoid accidental damage. This preparation will streamline the repair process and minimize risks. Proper planning and safety measures are key to successful maintenance of your Bissell ProHeat 2X.

Disassembling and Reassembling the Machine

To disassemble the Bissell ProHeat 2X, start by removing the upper housing assembly using a screwdriver. This grants access to internal components like the wiring and plumbing systems. Next, detach the lower brush housing and front nozzle assembly, referencing the exploded diagrams for clarity. When reassembling, ensure all parts are securely tightened and aligned properly. Reattach the upper housing last, verifying all screws are in place. Always refer to the parts diagram to confirm correct placement of components. Proper reassembly ensures optimal performance and prevents future malfunctions. Double-check for any loose connections or leaks before testing the machine.

Identifying the Correct Parts

Use the Bissell ProHeat 2X parts diagram to identify components accurately. Cross-reference model numbers and descriptions to ensure compatibility. Verify part numbers before ordering replacements for proper fitment.

Using the User Manual and Exploded Diagrams

The Bissell ProHeat 2X user manual and exploded diagrams are essential for identifying and locating parts. These resources provide detailed visual representations of each component, making it easier to understand how parts interact. By referencing the exploded diagrams, you can accurately pinpoint the specific part you need, ensuring you order the correct replacement. The manual also offers step-by-step instructions for disassembling and reassembling your machine, guiding you through the repair process efficiently. Utilize these tools to avoid errors and ensure your repairs are done correctly, extending the life of your Bissell ProHeat 2X.

Where to Find Genuine Bissell ProHeat 2X Parts

Genuine Bissell ProHeat 2X parts are available through authorized retailers like eVacuumStore.com and Vacuums R Us & Sewing Too. Visit BISSELL.com or call 1-800-237-7691 for authentic components.

Authorized Retailers and Online Suppliers

For genuine Bissell ProHeat 2X parts, visit authorized retailers like eVacuumStore.com or Vacuums R Us & Sewing Too. These suppliers provide authentic components, ensuring reliability and compatibility. You can also shop directly on BISSELL.com or contact their customer service at 1-800-237-7691 for assistance. Online platforms offer convenient access to exploded diagrams and model-specific parts lists, making it easier to identify what you need. Always verify the retailer’s authenticity to avoid counterfeit products. Genuine parts ensure optimal performance and extend the lifespan of your Bissell ProHeat 2X. Explore these trusted sources for all your repair and maintenance needs.

Thank you for using the Bissell ProHeat 2X repair manual. Regular maintenance and genuine parts ensure longevity and performance. This comprehensive guide helps you achieve professional cleaning results. Happy cleaning and enjoy a cleaner home!

Final Tips for Successful Repair and Maintenance

For optimal performance, always refer to the Bissell ProHeat 2X parts diagram and manual. Regularly inspect and clean brushes and nozzles to prevent clogs. Use genuine parts to ensure compatibility and longevity. Before any repair, disconnect power and wear protective gear. Follow disassembly steps carefully to avoid damage. Reassemble in reverse order and test functionality post-repair. Store the machine in a dry, cool place to prevent mold. Schedule annual professional servicing if possible. Keep the user manual handy for quick troubleshooting. By following these tips, you’ll extend the life of your ProHeat 2X and maintain its efficiency.